The Importance of Drying 3D Printing Supplies

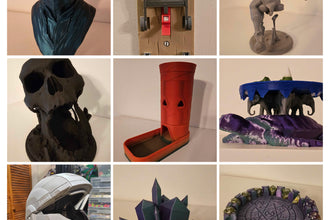

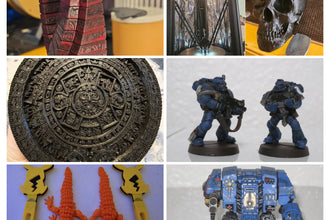

All FDM 3D printing materials are plastic polymers prone to moisture absorption, which can damage them if not stored correctly. The drier these materials are, the better the print quality. Therefore, it’s essential to ensure your materials are dry before printing. This guide provides comprehensive instructions on how to dry damp 3D printer materials, including recommended drying temperatures and durations for various types of materials.

3D printer materials like PLA, nylon, and ABS are hygroscopic, meaning they tend to absorb moisture. Nylon, ABS, and PVA are more susceptible to moisture absorption than PLA and PETG. However, it’s crucial to keep all materials dry before printing, as moisture can degrade their mechanical properties.

When the filament used for 3D printing absorbs moisture, it expands and becomes brittle, affecting print accuracy and quality. For high-quality 3D printing, it’s advisable to keep the filament as dry as possible. If your print materials become damp due to improper storage, don’t worry; there are simple and safe methods to dry them.

Identifying Wet Filament

The hygroscopic nature of the material means certain signs indicate the supplies are damp and need immediate drying before printing. Checking for changes in color and brittleness in the materials is a quick and easy method. Additionally, poor print quality or reduced bed adhesion may signal an issue with the material. Inspecting printer components like nozzles and extruders can also help determine if your filament needs drying.

Here are a few signs that your 3D printer materials may need drying:

- Poor print quality: This happens when the printer fails to extrude the damp filament adequately, leading to print defects such as severe pulling, poor draping, and bridge sagging.

- Poor performance: When the material contains moisture, it becomes brittle and soft, losing its original rigidity. Also, the color of damp filament tends to fade, lacking its original shine and vibrancy.

- Clogged nozzles: Material contaminated with internal impurities and moisture can clog nozzles, resulting in bubbles, popping sounds, and the release of water vapor during extrusion.

You can also use tools to check if the filament is damp. A moisture meter can check the filament for humidity and hidden moisture. Additionally, calipers can measure the filament’s diameter; a significant deviation from the initial diameter indicates it has absorbed moisture and expanded.

Effective Methods to Dry 3D Printer Materials

- Oven: Kitchen ovens can dry damp filaments and are a convenient household appliance. However, precise temperature control is necessary, often requiring the oven to be set at its lowest temperature. The internal temperature will usually be slightly higher than the set temperature after preheating, so use a thermometer to ensure it matches your target temperature. Place the filament on the middle or top shelf of the oven, avoiding close proximity to the heating element as this may damage the entire spool of filament. Finally, use an external thermometer to monitor that the oven maintains a steady temperature to prevent overheating and melting the filament.

- Food Dehydrators: If you want to enhance safety and stability when drying filament, consider using a food dehydrator. It’s designed to dry fruits, vegetables, and meats by slowly removing excess water at a low temperature, typically lower than that of an oven. The dehydrator’s round shape is ideal for filament spools, but it has a small capacity. It may only be able to dry one or two spools at a time. If you’re on a tight budget, buying a used food dehydrator is a good option.

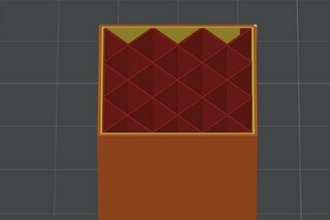

- Filament Dryers: Filament dryers are designed for 3D printing filaments rather than food products. They’re professional and easy to operate, with built-in timers and digital displays that significantly improve drying efficiency. Some filament dryers can even feed the printer while drying, saving drying time. The main drawback is cost; single-spool dryers typically cost $40 to $50, while dryers with two spools can cost $100 to $200.

The time and temperature required to dry the materials vary depending on the type of material. In general, drying damp filament usually takes about 4-6 hours. High-moisture materials, such as nylon and ABS, may require longer drying times. For heat-resistant filaments such as ABS, nylon, and ASA, drying temperatures and times are slightly higher than for other materials.

Preventing Filament Moisture

Proper storage of filaments ensures they remain dry at all times, effectively preventing damage from moisture and dust. When using well-protected materials, it’s not necessary to dry the filament every time you start printing. If your storage environment is somewhat humid, or if you cannot use up an open spool of filament within a month, it’s recommended that you store it in a plastic storage bag or box with a good seal. Moreover, combining the storage method with desiccant and a hygrometer can further enhance the drying effect. Regularly check the humidity of stored filaments and measure with calipers for signs of increased brittleness or changes in diameter to detect any swelling due to moisture absorption.

If you’ve been searching for a 3D printer with a large print surface and fast speeds recently, Flsun’s S1 is definitely worth considering. The Flsun S1 boasts an impressive print volume of 320x320x430mm and prints at speeds of up to 1,200mm/s, which is ten times faster than ordinary printers. Most importantly, the S1 printer itself comes with a filament drying function, so you no longer have to worry about printing errors caused by damp materials. This feature also saves on your printing costs and consumption, providing you with a more convenient printing experience.