In 3D printing, regardless of the technique employed, various pitfalls can lead to suboptimal parts. A critical yet often neglected aspect is wall thickness. This term refers to the outer wall or shell’s thickness of a 3D printed part, distinct from infill or layer height. Wall thickness is pivotal for the part’s stability and strength, but determining the appropriate minimum can be challenging.

Why is wall thickness crucial in 3D printing?

Wall thickness influences not only the aesthetics but also the strength and durability of the printed part. An incorrect thickness can result in a failed print. It’s even more vital than infill for the final product’s quality. Proper wall thickness helps prevent warpage; too thin, and the part may become brittle and prone to damage during or after printing. Post-processing can further compromise thin walls, making adherence to material-specific minimums essential.

Conversely, excessively thick walls waste materials and time, potentially causing heat dissipation issues and material shrinkage, leading to warpage.

Wall thickness is a key consideration in all 3D printing processes, particularly FDM. It’s material-dependent, with materials like PLA having a minimum thickness of 0.8 millimeters, though ideally closer to 1.5 millimeters. Flexible materials like TPU require a higher minimum of around 2.0 mm.

Tips for FDM 3D Printing Wall Thickness:

- Commonly, wall thickness is set as a multiple of the nozzle diameter, typically 0.4mm.

- A recommended minimum is 0.8mm, or twice the nozzle diameter.

- For increased strength, consider three to four times the nozzle diameter, between 1.2 mm and 1.6 mm.

- Aim for whole number multiples of the nozzle diameter to avoid overlapping outer wall layers and slowing print speed.

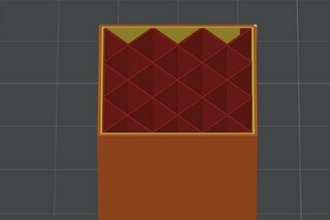

Not all 3D modeling software accounts for wall thickness, so it’s crucial to consider this early in the design process. Slicing software can help identify and correct too-thin walls before printing.

For fine details, slicing software’s “Detect Fine Features” parameter allows printing walls as thin as the nozzle diameter. “Vase mode” prints single continuous extrusion walls, ideal for waterproof vase-shaped objects.

Wall thickness may also be adjusted for parts with support structures, especially in fragile areas. High-resolution printers can produce thinner walls, but always within the material’s minimum requirements. Overall, understanding and applying the correct wall thickness is essential for successful 3D printing outcomes.